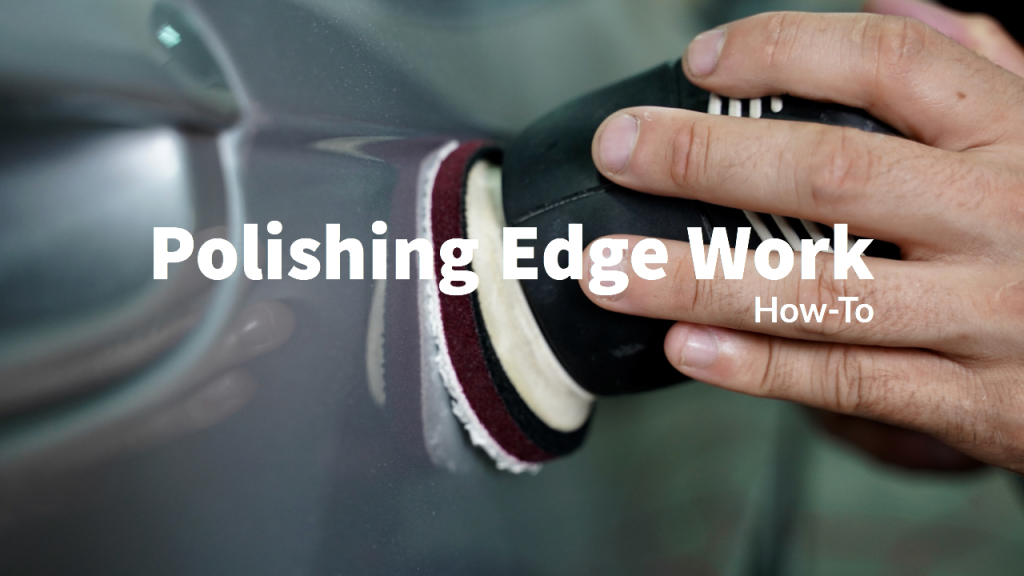

In this video, we talk about how to approach polishing edge work on a E39 M5. Just as the title suggests, edge work relates to the polishing of paint around edges, including door handles, trim, grilles, seals, etc. When I start a polishing process, I first grab a machine designed for edge work equipped with a small diameter backing plate like the Rupes Mini. Edgework can typically be a more time-consuming process and knocking it out first leaves you to then fill in (polish) the rest of the panel with a traditional sized polishing machine like the Rupes 21. Today we are fortunate to have a variety of tools tailored to polishing tight areas. Machines equipped with 1, 2, 3-inch backing plates allow the pad to make better contact with the paint which in turn leads to faster, more effective defect removal. In this video, we also talk about how trim removal and masking tape all aid in helping achieve a higher level of correction in the smallest of areas on a vehicle. Hope you enjoy!

Edge Work Tools

See more detailing videos at YouTube.com/DetailedImage.

Transcription

00:00

Hey guys, today I want to talk a little bit about edge work, how that translates into masking off different areas, how that relates to trim removal, all that kind of stuff. And I just, you know, edge work is one of those things where it’s awesome to dial in and correct the main body of a panel, right? The main zone, perfect defect removal you’re moving on. But what can be sometimes that the more time consuming part is all the edge works. So where defects are kind of getting loaded up right on this edge where you know, all around the door handle the kind of the ledge right at the top of the door where, cause originally there was this plastic trim piece right here on the door. Now in a normal, in a normal case, right, we would mass this off with tape and we would come in with at say a three inch polisher, you know, right up to that point.

00:54

And inevitably a little bit of polishing residue or tape residue, which can throw in another variable might get loaded up in that edge. By eliminating that trim piece, we can now get perfect contact with the edge of this. You know, this panel, you know, this, this, this this panel edge here. And you’re going to get a higher level of correction rate there without worrying about tape residue, without worrying about, you know, hurting this trim piece. So if there are paint and the same thing goes for emblems and things that are easily removable, but the last thing I want you to do is try to take, you know, take the car apart for something that maybe you shouldn’t come off or doesn’t have to come off. But if there are areas and they think about this, it was just, it was one, two, three, four, fives, six little clips popped right off and it’s going to allow us to now breeze through this door cutting phase without having to really like go slow around here and make sure we don’t damage the trim and it’s going to be tougher to get a high level of correction in in and around that edge.

01:55

So when it comes to trim removal, if possible, right. I would, you know, look into it, check out some YouTube videos, see if it’s doable in these on all these older BMWs, there’s always that plastic trim that kinda runs the, you know, the, the body of the car. And for us it just, it makes so much sense to try to remove those. It’ll just save you so much time. The second part when it comes to edge work is proper taping. Inevitably there are going to be things you just cannot remove, right? And you’re gonna have to mask them off with, with tape. Same thing. Like we’re going to, we’re going to be correcting this gloss black trim. We don’t want, we want to make sure that we are not going to load up or cover all these seals in in compound residues. So what we wanna do is there’s kind of a fine line because we don’t want the tape to cover what we want to Polish, but at the same time, we don’t want to load up or ruin any of the rubber seals.

02:50

So kind of taping right to that point is important. And then the, the other thing you want to just think about and consider is making sure that tape is really down. Because what happens sometimes is if you run a Polish or real close to a tape edge, the tape will, that little edge will lift up a little bit and guess what’s going to get into your pad, the adhesive, because I mean, the more things you throw into the equation, you’re already removing clear-coat. You’re already have abrasives that are getting diminished. The last thing you want then is adhesive adhesive to get thrown in the mix to to add to, you know, the workload and then potentially change your result. So just something to think about from a changing, from a tape perspective. And the last thing I’ll, I guess I’ll say is, as far as edge work goes is I always have multiple smaller machines to do a lot of my tight work edge work, that kind of stuff.

03:48

I have the the Rupes iBrid. I have the the Rupes Mini and what this is going to allow me to do is typically make better contact with an edge without having to worry about adjacent things, right. Same thing with this door handle. I like to match the diameter of my pad to the surface area I’m working on and it comes more from, you might get better rotation with pad rotation backing plate rotation with a smaller machine than you would a big one in some of these tighter areas. And ultimately you’ll probably get a higher correction rate. So when I’m approaching, for example, when I’m approaching this panel, what I’m, I’ll take something like the Rupes 21 I’ll knock out this main zone with now this trim removed, I’m gonna probably be able to get pretty darn close with the Rupes 21 that five inch pad, a five and a half, five and a half inch pad.

04:44

But when it comes to here, here, this ledge, then I’m going to be switching over to the mini to get better contact, to get better pad rotation and to allow me to, to remove those defects within these ledges. Same thing with the iBrid. I might select something like this for these areas, right? Cause at the same time with edge work, you also want to be, the reason we’re not hammering down with a larger machine is because we’re also very cognizant of edges. Edges typically have a little bit of less clear coat, meaning they’re a little bit more dangerous to, to polish on. We don’t want to hammer down on an edge and potentially burn it. So that’s another reason we’re matching the diameter of the pad backing plate to the surface. We’re working on. You know, for example, the reason I’m selecting the iBrid in this case is that even with a mini right, I’m going to have to make, I mean, you could, you could do this.

05:38

I mean that would probably work, but you’re going to, inevitably, there’s going to be a lot of pressure on, on this edge. And in some cases we wouldn’t be able to measure this particular piece. If it’s like a, a plastic or something and it’s just, it’s not necessarily unsafe, but there might be some risk thrown into the equation that you could avoid if you paired something like this is a one inch backing plate. You came in here and polished it this way. We’re so fortunate now to have so many different tools to be, to be able to approach tight, small areas. I think it definitely makes sense to take advantage of those and reduce our risk and heighten our, or increase our level of corrective ability on those tight edges. I hope this helped guys talk to you soon.